The Latest Capacitor Model and Procurement Models for Equipment Components

I. Introduction

Capacitors are fundamental components in electronic devices, playing a crucial role in energy storage, filtering, and signal processing. As technology advances, the demand for more efficient and compact capacitors has surged, leading to innovations that enhance performance and application versatility. Alongside these advancements, the procurement models for sourcing equipment components have evolved, reflecting the dynamic nature of the electronics industry. This article aims to explore the latest capacitor models and the various procurement strategies that companies can adopt to optimize their sourcing processes.

II. Understanding Capacitors

A. Definition and Function of Capacitors

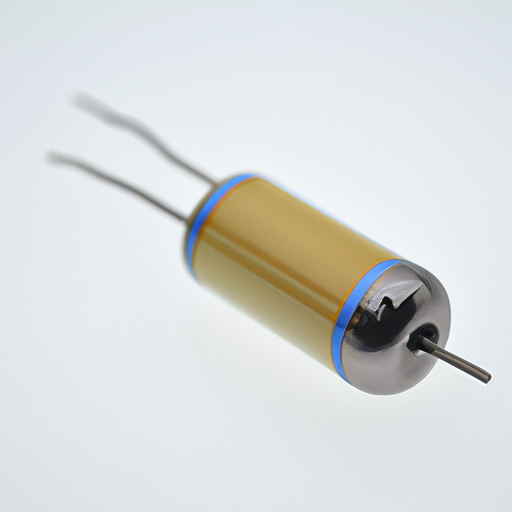

A capacitor is an electronic component that stores electrical energy in an electric field. It consists of two conductive plates separated by an insulating material, known as a dielectric. When voltage is applied, an electric field forms between the plates, allowing the capacitor to store energy. Capacitors are essential in various applications, including power supply smoothing, signal coupling, and timing circuits.

B. Types of Capacitors

1. **Ceramic Capacitors**: Known for their small size and reliability, ceramic capacitors are widely used in high-frequency applications. They are available in various capacitance values and voltage ratings.

2. **Electrolytic Capacitors**: These capacitors offer high capacitance values and are typically used in power supply circuits. They are polarized, meaning they must be connected in the correct direction to function properly.

3. **Film Capacitors**: Made from thin plastic films, these capacitors are known for their stability and low loss characteristics. They are commonly used in audio and high-frequency applications.

4. **Tantalum Capacitors**: Tantalum capacitors are known for their high capacitance in a small package. They are often used in applications where space is limited, such as in mobile devices.

5. **Supercapacitors**: Also known as ultracapacitors, these components can store large amounts of energy and are used in applications requiring rapid charge and discharge cycles, such as in electric vehicles and renewable energy systems.

C. Recent Advancements in Capacitor Technology

Recent advancements in capacitor technology have focused on enhancing performance and miniaturization. High-capacity and miniaturized designs have emerged, allowing for greater energy storage in smaller packages. Additionally, capacitors are increasingly being integrated into renewable energy systems and electric vehicles, where efficiency and reliability are paramount.

III. The Latest Capacitor Models

A. Overview of the Latest Capacitor Models in the Market

The market for capacitors is continuously evolving, with key manufacturers introducing innovative models that push the boundaries of performance. Companies like Murata, KEMET, and Vishay have been at the forefront of these advancements, offering capacitors with improved specifications and performance metrics.

B. Case Studies of New Capacitor Models

1. **Example 1: High-Density Capacitors for Consumer Electronics**

Recent models of high-density ceramic capacitors have been developed specifically for consumer electronics. These capacitors offer increased capacitance values while maintaining a compact size, making them ideal for smartphones and tablets.

2. **Example 2: Capacitors for Automotive Applications**

In the automotive sector, new tantalum capacitors have been designed to withstand harsh environments and high temperatures. These capacitors are essential for electric vehicles, where reliability and performance are critical.

C. Future Trends in Capacitor Technology

The future of capacitor technology is promising, with trends pointing towards integration with smart technologies and a focus on sustainability. Manufacturers are exploring eco-friendly materials and designs that reduce environmental impact while maintaining performance.

IV. Procurement Models for Equipment Components

A. Definition and Importance of Procurement Models

Procurement models refer to the strategies and processes organizations use to acquire goods and services. In the electronics industry, effective procurement is vital for ensuring the timely availability of components, managing costs, and maintaining quality.

B. Types of Procurement Models

1. **Traditional Procurement**

- **Description and Process**: This model involves a straightforward purchasing process where buyers request quotes from suppliers and select the best offer.

- **Advantages and Disadvantages**: While traditional procurement is simple, it can be time-consuming and may not always yield the best prices.

2. **Just-in-Time (JIT) Procurement**

- **Description and Process**: JIT procurement focuses on receiving goods only as they are needed in the production process, minimizing inventory costs.

- **Advantages and Disadvantages**: JIT can reduce waste and lower costs but may lead to supply chain vulnerabilities if disruptions occur.

3. **Strategic Sourcing**

- **Description and Process**: This model involves a comprehensive analysis of an organization’s purchasing needs and supplier capabilities to develop long-term relationships.

- **Advantages and Disadvantages**: Strategic sourcing can lead to better pricing and quality but requires significant time and resources to implement.

4. **E-Procurement**

- **Description and Process**: E-procurement utilizes digital platforms to streamline the purchasing process, allowing for easier supplier management and order tracking.

- **Advantages and Disadvantages**: E-procurement can enhance efficiency and transparency but may require upfront investment in technology.

C. Factors Influencing Procurement Decisions

Several factors influence procurement decisions in the electronics industry, including:

1. **Cost Considerations**: Price remains a primary factor, with companies seeking to balance quality and affordability.

2. **Supplier Reliability and Quality**: The reputation and reliability of suppliers are critical in ensuring consistent quality and timely delivery.

3. **Lead Times and Inventory Management**: Companies must consider lead times to avoid production delays and manage inventory effectively.

4. **Technological Advancements**: Staying updated on technological trends can influence procurement strategies and supplier selection.

V. Integrating Capacitor Procurement into Equipment Component Strategies

A. Aligning Capacitor Selection with Procurement Models

To optimize procurement, organizations must align their capacitor selection with their chosen procurement model. This alignment ensures that the right components are sourced efficiently and cost-effectively.

B. Best Practices for Sourcing Capacitors

1. **Supplier Evaluation and Selection**: Conduct thorough evaluations of potential suppliers based on quality, reliability, and performance metrics.

2. **Negotiation Strategies**: Develop effective negotiation strategies to secure favorable terms and pricing.

3. **Quality Assurance and Testing**: Implement rigorous quality assurance processes to ensure that sourced capacitors meet required specifications.

C. Case Studies of Successful Capacitor Procurement Strategies

1. **Example 1: A Tech Company’s Approach to Capacitor Sourcing**

A leading tech company adopted a strategic sourcing model, focusing on long-term relationships with suppliers. This approach allowed them to negotiate better pricing and ensure consistent quality for their capacitor needs.

2. **Example 2: An Automotive Manufacturer’s Procurement Model**

An automotive manufacturer implemented JIT procurement for capacitors, reducing inventory costs while maintaining a reliable supply chain. This model enabled them to respond quickly to market demands and minimize waste.

VI. Challenges in Capacitor Procurement

A. Supply Chain Disruptions

Supply chain disruptions, such as those caused by natural disasters or geopolitical tensions, can significantly impact the availability of capacitors. Companies must develop contingency plans to mitigate these risks.

B. Market Volatility and Pricing Fluctuations

The electronics market is subject to volatility, with pricing fluctuations affecting procurement budgets. Organizations must stay informed about market trends to make timely purchasing decisions.

C. Regulatory Compliance and Environmental Considerations

Compliance with regulations regarding materials and environmental impact is essential in capacitor procurement. Companies must ensure that their suppliers adhere to these standards.

D. Strategies to Mitigate Procurement Challenges

To address procurement challenges, organizations can implement strategies such as diversifying their supplier base, investing in technology for better supply chain visibility, and fostering strong relationships with key suppliers.

VII. Conclusion

In conclusion, capacitors are vital components in modern electronics, and understanding the latest models and procurement strategies is essential for manufacturers. As technology continues to evolve, so too will the approaches to sourcing these critical components. By aligning capacitor selection with effective procurement models, companies can enhance their operational efficiency and maintain a competitive edge in the market. The future of capacitor technology and procurement strategies promises exciting developments, paving the way for innovation in electronics manufacturing.

VIII. References

A comprehensive list of academic papers, industry reports, and articles used for research, along with additional resources for further reading on capacitors and procurement models, would be included here to support the information presented in the article.

The Latest Capacitor Model and Procurement Models for Equipment Components

I. Introduction

Capacitors are fundamental components in electronic devices, playing a crucial role in energy storage, filtering, and signal processing. As technology advances, the demand for more efficient and compact capacitors has surged, leading to innovations that enhance performance and application versatility. Alongside these advancements, the procurement models for sourcing equipment components have evolved, reflecting the dynamic nature of the electronics industry. This article aims to explore the latest capacitor models and the various procurement strategies that companies can adopt to optimize their sourcing processes.

II. Understanding Capacitors

A. Definition and Function of Capacitors

A capacitor is an electronic component that stores electrical energy in an electric field. It consists of two conductive plates separated by an insulating material, known as a dielectric. When voltage is applied, an electric field forms between the plates, allowing the capacitor to store energy. Capacitors are essential in various applications, including power supply smoothing, signal coupling, and timing circuits.

B. Types of Capacitors

1. **Ceramic Capacitors**: Known for their small size and reliability, ceramic capacitors are widely used in high-frequency applications. They are available in various capacitance values and voltage ratings.

2. **Electrolytic Capacitors**: These capacitors offer high capacitance values and are typically used in power supply circuits. They are polarized, meaning they must be connected in the correct direction to function properly.

3. **Film Capacitors**: Made from thin plastic films, these capacitors are known for their stability and low loss characteristics. They are commonly used in audio and high-frequency applications.

4. **Tantalum Capacitors**: Tantalum capacitors are known for their high capacitance in a small package. They are often used in applications where space is limited, such as in mobile devices.

5. **Supercapacitors**: Also known as ultracapacitors, these components can store large amounts of energy and are used in applications requiring rapid charge and discharge cycles, such as in electric vehicles and renewable energy systems.

C. Recent Advancements in Capacitor Technology

Recent advancements in capacitor technology have focused on enhancing performance and miniaturization. High-capacity and miniaturized designs have emerged, allowing for greater energy storage in smaller packages. Additionally, capacitors are increasingly being integrated into renewable energy systems and electric vehicles, where efficiency and reliability are paramount.

III. The Latest Capacitor Models

A. Overview of the Latest Capacitor Models in the Market

The market for capacitors is continuously evolving, with key manufacturers introducing innovative models that push the boundaries of performance. Companies like Murata, KEMET, and Vishay have been at the forefront of these advancements, offering capacitors with improved specifications and performance metrics.

B. Case Studies of New Capacitor Models

1. **Example 1: High-Density Capacitors for Consumer Electronics**

Recent models of high-density ceramic capacitors have been developed specifically for consumer electronics. These capacitors offer increased capacitance values while maintaining a compact size, making them ideal for smartphones and tablets.

2. **Example 2: Capacitors for Automotive Applications**

In the automotive sector, new tantalum capacitors have been designed to withstand harsh environments and high temperatures. These capacitors are essential for electric vehicles, where reliability and performance are critical.

C. Future Trends in Capacitor Technology

The future of capacitor technology is promising, with trends pointing towards integration with smart technologies and a focus on sustainability. Manufacturers are exploring eco-friendly materials and designs that reduce environmental impact while maintaining performance.

IV. Procurement Models for Equipment Components

A. Definition and Importance of Procurement Models

Procurement models refer to the strategies and processes organizations use to acquire goods and services. In the electronics industry, effective procurement is vital for ensuring the timely availability of components, managing costs, and maintaining quality.

B. Types of Procurement Models

1. **Traditional Procurement**

- **Description and Process**: This model involves a straightforward purchasing process where buyers request quotes from suppliers and select the best offer.

- **Advantages and Disadvantages**: While traditional procurement is simple, it can be time-consuming and may not always yield the best prices.

2. **Just-in-Time (JIT) Procurement**

- **Description and Process**: JIT procurement focuses on receiving goods only as they are needed in the production process, minimizing inventory costs.

- **Advantages and Disadvantages**: JIT can reduce waste and lower costs but may lead to supply chain vulnerabilities if disruptions occur.

3. **Strategic Sourcing**

- **Description and Process**: This model involves a comprehensive analysis of an organization’s purchasing needs and supplier capabilities to develop long-term relationships.

- **Advantages and Disadvantages**: Strategic sourcing can lead to better pricing and quality but requires significant time and resources to implement.

4. **E-Procurement**

- **Description and Process**: E-procurement utilizes digital platforms to streamline the purchasing process, allowing for easier supplier management and order tracking.

- **Advantages and Disadvantages**: E-procurement can enhance efficiency and transparency but may require upfront investment in technology.

C. Factors Influencing Procurement Decisions

Several factors influence procurement decisions in the electronics industry, including:

1. **Cost Considerations**: Price remains a primary factor, with companies seeking to balance quality and affordability.

2. **Supplier Reliability and Quality**: The reputation and reliability of suppliers are critical in ensuring consistent quality and timely delivery.

3. **Lead Times and Inventory Management**: Companies must consider lead times to avoid production delays and manage inventory effectively.

4. **Technological Advancements**: Staying updated on technological trends can influence procurement strategies and supplier selection.

V. Integrating Capacitor Procurement into Equipment Component Strategies

A. Aligning Capacitor Selection with Procurement Models

To optimize procurement, organizations must align their capacitor selection with their chosen procurement model. This alignment ensures that the right components are sourced efficiently and cost-effectively.

B. Best Practices for Sourcing Capacitors

1. **Supplier Evaluation and Selection**: Conduct thorough evaluations of potential suppliers based on quality, reliability, and performance metrics.

2. **Negotiation Strategies**: Develop effective negotiation strategies to secure favorable terms and pricing.

3. **Quality Assurance and Testing**: Implement rigorous quality assurance processes to ensure that sourced capacitors meet required specifications.

C. Case Studies of Successful Capacitor Procurement Strategies

1. **Example 1: A Tech Company’s Approach to Capacitor Sourcing**

A leading tech company adopted a strategic sourcing model, focusing on long-term relationships with suppliers. This approach allowed them to negotiate better pricing and ensure consistent quality for their capacitor needs.

2. **Example 2: An Automotive Manufacturer’s Procurement Model**

An automotive manufacturer implemented JIT procurement for capacitors, reducing inventory costs while maintaining a reliable supply chain. This model enabled them to respond quickly to market demands and minimize waste.

VI. Challenges in Capacitor Procurement

A. Supply Chain Disruptions

Supply chain disruptions, such as those caused by natural disasters or geopolitical tensions, can significantly impact the availability of capacitors. Companies must develop contingency plans to mitigate these risks.

B. Market Volatility and Pricing Fluctuations

The electronics market is subject to volatility, with pricing fluctuations affecting procurement budgets. Organizations must stay informed about market trends to make timely purchasing decisions.

C. Regulatory Compliance and Environmental Considerations

Compliance with regulations regarding materials and environmental impact is essential in capacitor procurement. Companies must ensure that their suppliers adhere to these standards.

D. Strategies to Mitigate Procurement Challenges

To address procurement challenges, organizations can implement strategies such as diversifying their supplier base, investing in technology for better supply chain visibility, and fostering strong relationships with key suppliers.

VII. Conclusion

In conclusion, capacitors are vital components in modern electronics, and understanding the latest models and procurement strategies is essential for manufacturers. As technology continues to evolve, so too will the approaches to sourcing these critical components. By aligning capacitor selection with effective procurement models, companies can enhance their operational efficiency and maintain a competitive edge in the market. The future of capacitor technology and procurement strategies promises exciting developments, paving the way for innovation in electronics manufacturing.

VIII. References

A comprehensive list of academic papers, industry reports, and articles used for research, along with additional resources for further reading on capacitors and procurement models, would be included here to support the information presented in the article.