What are the Popular Fan Capacitor Product Types?

I. Introduction

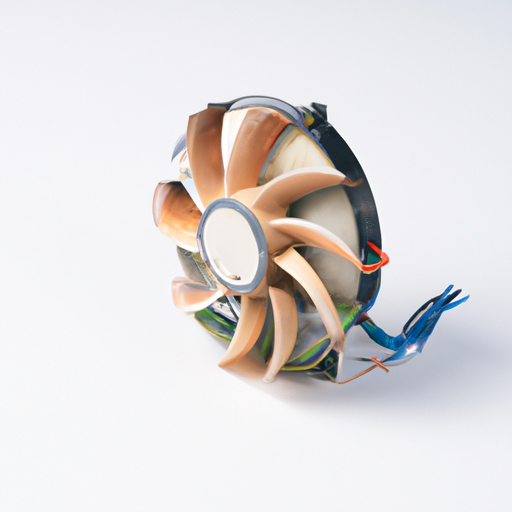

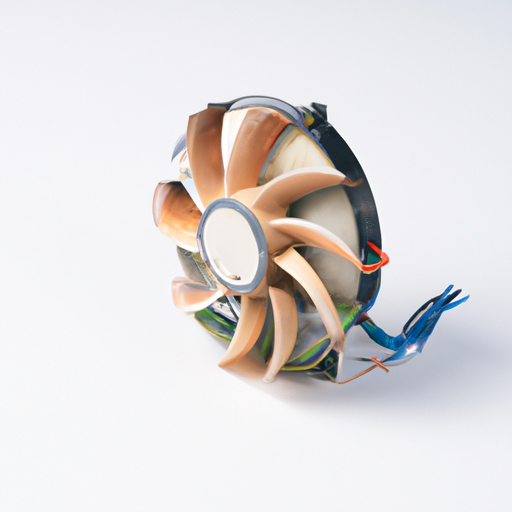

Fan capacitors are essential components in various electrical systems, particularly in fans and motors. They play a crucial role in ensuring efficient operation, enhancing performance, and prolonging the lifespan of electrical devices. This article aims to provide a comprehensive overview of fan capacitors, their types, specifications, popular brands, and maintenance tips, helping readers make informed decisions when selecting the right capacitor for their needs.

II. Understanding Fan Capacitors

A. What is a Capacitor?

A capacitor is an electronic component that stores electrical energy in an electric field. It consists of two conductive plates separated by an insulating material known as a dielectric. The basic principle of capacitance is that when a voltage is applied across the plates, an electric charge accumulates, allowing the capacitor to store energy. In electrical circuits, capacitors serve various functions, including filtering, timing, and energy storage.

B. Specific Functions of Fan Capacitors

Fan capacitors are specifically designed to enhance the performance of electric fans and motors. They serve two primary functions:

1. **Starting and Running Capacitors**: These capacitors provide the necessary torque to start the motor and maintain its operation.

2. **Phase Shift and Power Factor Correction**: They help in creating a phase shift in the current, improving the power factor and overall efficiency of the motor.

III. Types of Fan Capacitors

A. Permanent Split Capacitor (PSC)

**Description and Working Principle**: A Permanent Split Capacitor (PSC) is a type of capacitor that remains connected to the motor circuit at all times. It provides a continuous phase shift, allowing the motor to run efficiently.

**Applications**: PSCs are commonly used in ceiling fans, exhaust fans, and other applications where continuous operation is required.

**Advantages and Disadvantages**: The main advantage of PSCs is their simplicity and reliability. However, they may not provide sufficient starting torque for larger motors.

B. Dual Run Capacitor

**Definition and Functionality**: A Dual Run Capacitor combines two capacitors in one housing, allowing it to serve both starting and running functions for two different motors.

**Use in HVAC Systems**: These capacitors are widely used in HVAC systems, where multiple fan motors operate simultaneously.

**Pros and Cons**: The primary advantage of dual run capacitors is their space-saving design. However, if one capacitor fails, it can affect the performance of both motors.

C. Start Capacitor

**Purpose and Operation**: Start capacitors are designed to provide a boost of energy to start the motor. They are only connected during the startup phase and are disconnected once the motor reaches a certain speed.

**Common Applications**: These capacitors are typically used in single-phase motors, such as those found in air conditioning units and refrigeration systems.

**Benefits and Limitations**: Start capacitors offer high starting torque, but they are not suitable for continuous operation, as they can overheat if left connected.

D. Run Capacitor

**Explanation and Significance**: Run capacitors are used in motors that require continuous operation. They remain connected throughout the motor's operation, providing a consistent phase shift.

**Usage in Continuous Operation Scenarios**: Run capacitors are commonly found in air conditioning units, ceiling fans, and other appliances that run for extended periods.

**Advantages and Disadvantages**: The main advantage of run capacitors is their ability to improve motor efficiency. However, they can be more expensive than other types of capacitors.

E. Capacitor-Start Capacitor-Run (CSCR)

**Overview of the CSCR Design**: The CSCR design combines both start and run capacitors in one unit, providing the benefits of both types.

**Applications in High-Efficiency Motors**: CSCR capacitors are often used in high-efficiency motors, where both starting torque and continuous operation are required.

**Benefits and Challenges**: The primary benefit of CSCR capacitors is their versatility. However, they can be more complex and costly compared to standard capacitors.

IV. Key Specifications and Features

A. Voltage Ratings

**Importance of Selecting the Correct Voltage**: Choosing the correct voltage rating for a fan capacitor is crucial to ensure safe and efficient operation. Using a capacitor with a lower voltage rating than required can lead to failure and potential hazards.

**Common Voltage Ratings**: Fan capacitors typically come in voltage ratings of 250V, 370V, and 440V, depending on the application.

B. Capacitance Values

**Understanding Microfarads (µF)**: Capacitance is measured in microfarads (µF), and it indicates the capacitor's ability to store electrical energy. The higher the capacitance, the more energy the capacitor can store.

**How Capacitance Affects Performance**: Selecting the correct capacitance value is essential for optimal motor performance. An incorrect value can lead to inefficient operation or motor failure.

C. Temperature Ratings

**Impact of Temperature on Capacitor Lifespan**: Temperature can significantly affect the lifespan of a capacitor. High temperatures can cause the dielectric material to degrade, leading to failure.

**Common Temperature Ratings**: Fan capacitors are typically rated for temperatures ranging from -40°C to 85°C, with some high-performance capacitors rated for even higher temperatures.

D. Physical Size and Mounting Options

**Importance of Size in Installation**: The physical size of a capacitor is crucial for installation, as it must fit within the designated space in the fan or motor housing.

**Different Mounting Styles**: Capacitors come in various mounting styles, including bracket-mounted and snap-in designs, allowing for flexibility in installation.

V. Popular Brands and Manufacturers

A. Overview of Leading Brands in the Fan Capacitor Market

1. **Brand A**: Known for its high-quality capacitors, Brand A offers a wide range of products suitable for various applications. Their reputation for reliability makes them a popular choice among consumers.

2. **Brand B**: This brand is recognized for its innovative designs and advanced technology in capacitor manufacturing. They focus on energy efficiency and performance, catering to the needs of modern electrical systems.

3. **Brand C**: With a strong customer feedback system, Brand C has built a reputation for producing durable and reliable fan capacitors. Their products are often praised for their longevity and performance.

B. Comparison of Product Quality and Pricing

When selecting a fan capacitor, it's essential to compare product quality and pricing among different brands. While some brands may offer lower prices, it's crucial to consider the long-term reliability and performance of the capacitor.

VI. Installation and Maintenance

A. Importance of Proper Installation

**Safety Considerations**: Proper installation of fan capacitors is vital for safety. Incorrect installation can lead to electrical hazards, including short circuits and fires.

**Tools and Equipment Needed**: Basic tools such as screwdrivers, pliers, and a multimeter are typically required for capacitor installation. It's essential to follow the manufacturer's instructions for safe installation.

B. Maintenance Tips for Fan Capacitors

**Regular Inspection and Testing**: Regularly inspecting and testing fan capacitors can help identify potential issues before they lead to failure. Look for signs of wear, such as bulging or leaking.

**Signs of Failure and When to Replace**: Common signs of capacitor failure include unusual noises, reduced performance, and overheating. If any of these symptoms occur, it's essential to replace the capacitor promptly to avoid further damage to the motor.

VII. Conclusion

In conclusion, fan capacitors are vital components in electrical systems, ensuring efficient operation and performance of fans and motors. Understanding the different types of fan capacitors, their specifications, and maintenance requirements is crucial for selecting the right product for specific needs. By considering factors such as voltage ratings, capacitance values, and brand reputation, consumers can make informed decisions that enhance the longevity and efficiency of their electrical devices.

VIII. References

For further reading and resources on fan capacitors, consider exploring the following:

1. Manufacturer websites for detailed product specifications.

2. Electrical engineering textbooks covering capacitor theory and applications.

3. Online forums and communities for user experiences and recommendations on fan capacitors.

By staying informed and proactive about fan capacitor maintenance and selection, users can ensure optimal performance and safety in their electrical systems.

What are the Popular Fan Capacitor Product Types?

I. Introduction

Fan capacitors are essential components in various electrical systems, particularly in fans and motors. They play a crucial role in ensuring efficient operation, enhancing performance, and prolonging the lifespan of electrical devices. This article aims to provide a comprehensive overview of fan capacitors, their types, specifications, popular brands, and maintenance tips, helping readers make informed decisions when selecting the right capacitor for their needs.

II. Understanding Fan Capacitors

A. What is a Capacitor?

A capacitor is an electronic component that stores electrical energy in an electric field. It consists of two conductive plates separated by an insulating material known as a dielectric. The basic principle of capacitance is that when a voltage is applied across the plates, an electric charge accumulates, allowing the capacitor to store energy. In electrical circuits, capacitors serve various functions, including filtering, timing, and energy storage.

B. Specific Functions of Fan Capacitors

Fan capacitors are specifically designed to enhance the performance of electric fans and motors. They serve two primary functions:

1. **Starting and Running Capacitors**: These capacitors provide the necessary torque to start the motor and maintain its operation.

2. **Phase Shift and Power Factor Correction**: They help in creating a phase shift in the current, improving the power factor and overall efficiency of the motor.

III. Types of Fan Capacitors

A. Permanent Split Capacitor (PSC)

**Description and Working Principle**: A Permanent Split Capacitor (PSC) is a type of capacitor that remains connected to the motor circuit at all times. It provides a continuous phase shift, allowing the motor to run efficiently.

**Applications**: PSCs are commonly used in ceiling fans, exhaust fans, and other applications where continuous operation is required.

**Advantages and Disadvantages**: The main advantage of PSCs is their simplicity and reliability. However, they may not provide sufficient starting torque for larger motors.

B. Dual Run Capacitor

**Definition and Functionality**: A Dual Run Capacitor combines two capacitors in one housing, allowing it to serve both starting and running functions for two different motors.

**Use in HVAC Systems**: These capacitors are widely used in HVAC systems, where multiple fan motors operate simultaneously.

**Pros and Cons**: The primary advantage of dual run capacitors is their space-saving design. However, if one capacitor fails, it can affect the performance of both motors.

C. Start Capacitor

**Purpose and Operation**: Start capacitors are designed to provide a boost of energy to start the motor. They are only connected during the startup phase and are disconnected once the motor reaches a certain speed.

**Common Applications**: These capacitors are typically used in single-phase motors, such as those found in air conditioning units and refrigeration systems.

**Benefits and Limitations**: Start capacitors offer high starting torque, but they are not suitable for continuous operation, as they can overheat if left connected.

D. Run Capacitor

**Explanation and Significance**: Run capacitors are used in motors that require continuous operation. They remain connected throughout the motor's operation, providing a consistent phase shift.

**Usage in Continuous Operation Scenarios**: Run capacitors are commonly found in air conditioning units, ceiling fans, and other appliances that run for extended periods.

**Advantages and Disadvantages**: The main advantage of run capacitors is their ability to improve motor efficiency. However, they can be more expensive than other types of capacitors.

E. Capacitor-Start Capacitor-Run (CSCR)

**Overview of the CSCR Design**: The CSCR design combines both start and run capacitors in one unit, providing the benefits of both types.

**Applications in High-Efficiency Motors**: CSCR capacitors are often used in high-efficiency motors, where both starting torque and continuous operation are required.

**Benefits and Challenges**: The primary benefit of CSCR capacitors is their versatility. However, they can be more complex and costly compared to standard capacitors.

IV. Key Specifications and Features

A. Voltage Ratings

**Importance of Selecting the Correct Voltage**: Choosing the correct voltage rating for a fan capacitor is crucial to ensure safe and efficient operation. Using a capacitor with a lower voltage rating than required can lead to failure and potential hazards.

**Common Voltage Ratings**: Fan capacitors typically come in voltage ratings of 250V, 370V, and 440V, depending on the application.

B. Capacitance Values

**Understanding Microfarads (µF)**: Capacitance is measured in microfarads (µF), and it indicates the capacitor's ability to store electrical energy. The higher the capacitance, the more energy the capacitor can store.

**How Capacitance Affects Performance**: Selecting the correct capacitance value is essential for optimal motor performance. An incorrect value can lead to inefficient operation or motor failure.

C. Temperature Ratings

**Impact of Temperature on Capacitor Lifespan**: Temperature can significantly affect the lifespan of a capacitor. High temperatures can cause the dielectric material to degrade, leading to failure.

**Common Temperature Ratings**: Fan capacitors are typically rated for temperatures ranging from -40°C to 85°C, with some high-performance capacitors rated for even higher temperatures.

D. Physical Size and Mounting Options

**Importance of Size in Installation**: The physical size of a capacitor is crucial for installation, as it must fit within the designated space in the fan or motor housing.

**Different Mounting Styles**: Capacitors come in various mounting styles, including bracket-mounted and snap-in designs, allowing for flexibility in installation.

V. Popular Brands and Manufacturers

A. Overview of Leading Brands in the Fan Capacitor Market

1. **Brand A**: Known for its high-quality capacitors, Brand A offers a wide range of products suitable for various applications. Their reputation for reliability makes them a popular choice among consumers.

2. **Brand B**: This brand is recognized for its innovative designs and advanced technology in capacitor manufacturing. They focus on energy efficiency and performance, catering to the needs of modern electrical systems.

3. **Brand C**: With a strong customer feedback system, Brand C has built a reputation for producing durable and reliable fan capacitors. Their products are often praised for their longevity and performance.

B. Comparison of Product Quality and Pricing

When selecting a fan capacitor, it's essential to compare product quality and pricing among different brands. While some brands may offer lower prices, it's crucial to consider the long-term reliability and performance of the capacitor.

VI. Installation and Maintenance

A. Importance of Proper Installation

**Safety Considerations**: Proper installation of fan capacitors is vital for safety. Incorrect installation can lead to electrical hazards, including short circuits and fires.

**Tools and Equipment Needed**: Basic tools such as screwdrivers, pliers, and a multimeter are typically required for capacitor installation. It's essential to follow the manufacturer's instructions for safe installation.

B. Maintenance Tips for Fan Capacitors

**Regular Inspection and Testing**: Regularly inspecting and testing fan capacitors can help identify potential issues before they lead to failure. Look for signs of wear, such as bulging or leaking.

**Signs of Failure and When to Replace**: Common signs of capacitor failure include unusual noises, reduced performance, and overheating. If any of these symptoms occur, it's essential to replace the capacitor promptly to avoid further damage to the motor.

VII. Conclusion

In conclusion, fan capacitors are vital components in electrical systems, ensuring efficient operation and performance of fans and motors. Understanding the different types of fan capacitors, their specifications, and maintenance requirements is crucial for selecting the right product for specific needs. By considering factors such as voltage ratings, capacitance values, and brand reputation, consumers can make informed decisions that enhance the longevity and efficiency of their electrical devices.

VIII. References

For further reading and resources on fan capacitors, consider exploring the following:

1. Manufacturer websites for detailed product specifications.

2. Electrical engineering textbooks covering capacitor theory and applications.

3. Online forums and communities for user experiences and recommendations on fan capacitors.

By staying informed and proactive about fan capacitor maintenance and selection, users can ensure optimal performance and safety in their electrical systems.